A backflow preventer allows water to flow exclusively in one direction. Its sole job is to prevent drinking water contamination from backflow events.

-

1Contact Information

-

2Additional Details

A backflow preventer allows water to flow exclusively in one direction. Its sole job is to prevent drinking water contamination from backflow events.

What is a Backflow Preventer?

A backflow preventer allows water to flow exclusively in one direction. Its sole job is to prevent drinking water contamination from backflow events.

A backflow preventer typically extends above ground, although it is common to see many installed inside the building or in underground vaults. For superior safety and ability to service and maintain, the preferred method of installation is outside of the building and above ground.

Water should only ever flow in one direction: into your building or home. On occasion, due to pressure changes in the pipes, water can actually flow backward and into the main water supply line.

Because backflow can transfer contaminated water back into the municipal water supply or elsewhere in your home, most commercial and industrial properties have three separate water taps: domestic, fire protection and landscape irrigation. Each line within a single property may or may not be fitted with a containment backflow prevention assembly.

Your backflow prevention assembly should be installed inside an above-ground enclosure. It’s the safest and most cost-effective place to put it.

Installing your backflow preventer above ground in an outdoor enclosure allows protection for your backflow preventer and provides for easy access. You also don’t have to worry about flooding your building if backflow were to occur and your backflow preventer functions as designed.

Installing a backflow preventer underground is not safe. People will do it for aesthetic reasons, but the fact is that this practice exposes property owners to liability and unnecessary risk. Toxic gasses can leak into a vault; wild animals can inhabit one, posing a danger to anyone who enters to test or repair equipment.

There are three options for backflow preventer installation: inside a vault, inside a building, or outside and above ground in an enclosure. This backflow preventer installation guide details each method and highlights why placing backflow preventers above ground and outside is not just best practice, but the clear choice for installation.

A subterranean vault is the legacy method still practiced among some designers today. As you probably know, an RPZ cannot be installed below-grade. In addition to being unsuitable for RPZs, there are compelling reasons to discontinue the use of vaults altogether.

Here are the two most important reasons why a vault should never be specified:

Backflow preventers are designed to stop cross connections from happening. Backflow preventer installation in a vault is counterproductive. Vaults flood. We've heard this for years from water jurisdictions and backflow testers alike throughout the country. In fact, a poll of engineers and water jurisdictions were asked about this during a webinar on backflow preventer installation. 70 percent said they know vaults flood.

A flooded vault causes a cross connection through submerged test cocks - whether they are open or closed. Read more on this topic in our blog post on utility vaults. There you'll find quotes from the USC Foundation for Cross Connection Control and Hydraulic Research's publication, Cross Talk. Their expert opinion on the matter is clear: vaults are a breeding ground for potential contamination.

The language from the FCCCHR says vaults may fill with water. One might wonder how often this really happens.The video below is a compilation of photos and videos sent in to us by testers in the field.

According to OSHA, water utility vaults or pits are considered a confined space. When a backflow in a vault is tested each year, the tester must climb down into this confined space. According to the National Institute for Occupational Safety and Health, 92 fatal injuries occur each year in confined spaces.

You might be think, ‘Testers are trained professionals, surely they know how to manage a confined space!" While that’s true, what about the building's maintenance person, property owner or adventurous kids who can access the vault simply by opening the lid? We have never seen confined space danger signs posted at or on the vault. Testers agree that there is little stopping curious people from opening them up.

You can read about these and another seven reasons to keep backflow preventers out of below-grade vaults here.

It’s almost as common to see a backflow preventer installed inside the building as it is to see one installed in a vault, especially since RPZs can't be installed below grade. Most plumbing engineers, building owners and property insurers are unaware of the potential flood risk an RPZ poses. Here is a video demonstrating a 3" RPZ dumping water. It may surprise you!

The key difference between a reduced pressure zone backflow assembly and a double check backflow assembly is that RPZs are designed to dump water to protect the water system. We have an in-depth article on the differences between DC and RPZ backflow preventers.

The most important thing a designer must understand is the worst case scenario: what can happen. What describes the ‘perfect storm? We all know that with an RPZ, when water demand stops, the water between the valves often evacuates into the relief valve. Many think that event defines the limit of what water can ever flow into a drain, but that simply isn't true. Watch the video below to watch an RPZ dumping water. We just happened to be driving by and stopped to investigate the water flowing out of this enclosure!

First let's look at a flow-stop situation, one that might naturally occur at the end of the day. It's possible, we'll look at a real example further down, that a small pebble can lodge in the #2 check valve. Now what if there's something nearby in the system that causes back siphon? Because the #2 check valve is not closing, all the water that has been delivered to the building will continue to flow out the relief valve until the private lines are cleared. If this is a four-story building, that’s a lot of water!

Now we'll consider a failure of the #1 check valve. Under normal operating conditions, this failure would go unnoticed. After all, water is being called for by the user through the opening of taps. The water flows in undeterred. But with this imbalance in the system, changes in demand tend to rock the remaining valves open and closed sporadically.

This creates the conditions for that ‘perfect storm’. The imbalance created by the #1 failure makes the relief valve more prone to opening momentarily, allowing debris to block the closure of that valve. Under such conditions, a constant flow of delivered water will begin to flow directly out the relief valve. This reduces water pressure for the user, but delivery will continue. The real damage begins when the user stops using water, such as at the end of a work day.

With the relief valve blocked open and the #1 valve inoperative, all the water that can be provided will flow unabated out the relief valve wherever it might be, and continue until the water source is interrupted.

This is the scenario that must be avoided: the perfect storm.

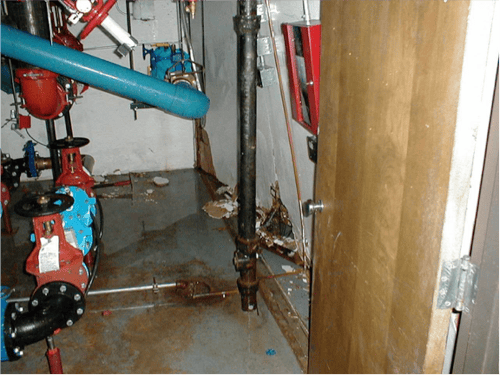

Here is an example of a catastrophic flood caused by an RPZ dumping water. Remember, the RPZ is exactly what it was designed to do. This flooding occurred in a hospital mechanical room causing over $1M in damage. You are looking at two sides of one wall. In the top photo, we see that the sudden water flow and volume moved the wall into the next room, which happened to be a telephone and low-voltage wiring room. You can see more of this in the photo below.

Here is an example of a catastrophic flood caused by an RPZ dumping water. Remember, the RPZ is exactly what it was designed to do. This flooding occurred in a hospital mechanical room causing over $1M in damage. You are looking at two sides of one wall. In the top photo, we see that the sudden water flow and volume moved the wall into the next room, which happened to be a telephone and low-voltage wiring room. You can see more of this in the photo below.

The insurer sought recovery from all the risk holders including the engineer, architect, contractor, subcontractor, even the most recent recorded tester; While the details of who paid what were not made public, we do know that the property insurer was made whole by one or more of the listed defendants.

This flood risk is still not common knowledge, but it should be. Backflow preventer manufacturers also make a flood control valve designed to be used in conjunction with reduced pressure zone devices. We've looked into how it operates and wrote an article about the Watts model of flood control valve. Some manufacturers have materials which show where they expect backflow valves to be installed: outside and above ground.

Additionally, backflow manufacturers make the relief valve discharge rates available to the public for all their RPZ models and sizes. To the right, you'll see the discharge rates for Wilkins RPZs from 1/4" to 10". Backflow manufacturers are making an effort to inform and prepare designers and property owners about the amount of water a relief valve can discharge. It's incumbent upon engineers to design the best backflow prevention solution possible for their respective use cases.

Some try to do this using drains, sinks or spouts. It's the most common way designers plan for water discharge. The problem is that these drains are too small to evacuate as much water as is necessary, especially for larger devices. In order to properly dispel all that water, you'd need either many drains, or very large ones. This comes with it's own problems - cost. A member of the Chicago ASPE Chapter, David DeBord, said in a 2013 article that “the floor drain capacity required for RPZs 3” diameter and larger are likely to be cost-prohibitive due to necessary pipe diameter and fall rates.”

Installing backflow preventers in below ground vaults poses an unnecessary risk to the water supply because of vault flooding. On the other hand, installing reduced pressure zone backflow assemblies indoors creates unnecessary risk to the building as well as designers through litigation.

How do you avoid all these risks? Install backflow preventers above ground and outside. This is the safest way to protect the property, maintenance personnel and testers, and yourself.

To protect the devices themselves, use protective enclosures. If you are ready to make the change to an above ground enclosure, here are your next steps:

Here's what you need to know about choosing an enclosure. It is important to make sure your enclosure manufacturer complies with the ASSE 1060 standard. This will ensure the enclosures are strong and rugged, have a locking mechanism and drainage, and will maintain the proper temperature for your climate. There are three classes of ASSE 1060 approved enclosures, and they provide different levels of protection from the elements. Make sure you get a Class 1 enclosure with the proper heater if you need freeze protection.

There are different materials available and you should choose the one that will perform best for your needs. The most common materials used for backflow enclosures are aluminum, fiberglass and cages. You may also see brick and block enclosures on the market.

Specifying an ASSE 1060 enclosure in the material of your choice will get you the strongest protection your project requires. You should also consider details such as color and size. Most manufacturers offer enclosures in different colors. For example, Safe-T-Cover enclosures come in four standard colors at no extra charge, including a green and tan for most landscaping environments. Other colors are available for an additional fee, and we can also do custom design wrapped enclosures, as well.

Also, the size of the enclosure can vary not only by the size of the device, but also the type. N-type backflow preventers have a significantly smaller footprint and therefore the enclosure may be up to 70% smaller than the enclosure for an inline backflow preventer. Both color and size aid in blending an enclosure into the landscaping of your project. You can also place the enclosure near the property line but not at the front entrance to avoid an eyesore.

Avoid the risks: Keep backflow preventers outside and above ground. Protect them with an enclosure.

Looking for a custom quote? Have questions?

Fill out the form via the button below and we will get back to you as quickly as possible.

We're in the office 8am-4pm Central Time, Monday through Friday.

© 2026 by Hydrocowl, Inc. All Rights Reserved.

Terms & Conditions | Privacy Policy