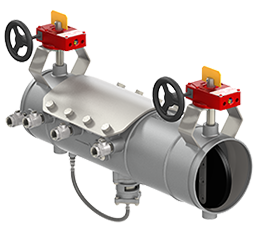

When you think of technological advances, it’s easy to think of some medical or scientific breakthrough or an advance in computing or telecommunications. You may not think of a backflow preventer as cutting-edge technology. The Ames Deringer backflow, though, is just that: an innovation in backflow technology that is truly a game changer in the market in more ways than one. In fact, it’s a game changer in three ways:

Size

The Ames Deringer is the shortest and lightest backflow preventer on the market, making installation easier than ever before. Where an installer may have needed a crew or heavy equipment to install or replace a backflow preventer in the past, the Ames Deringer is smaller and lighter while boasting features and functionality that makes heavy, iron preventers obsolete.

“Our 4" double-check with the integrated butterfly valves is 18 ¾" long and only weighs 42 pounds. Even up to a 4" double-check valve, one guy can go out there and install it,” said Brad Scott, regional channel manager for Watts Water Technologies, makers of the Ames Deringer.

“For [someone] installing a Deringer, it's going to be more difficult to pull the old valve out than to put the new one in.”

Reliability

The Ames Deringer also boasts an elegant simplicity in design with a stainless steel body, ensuring steady, reliable performance.

Where iron valves can struggle with hard water, corrosion and other variables that come through the water, the complete stainless steel assembly offers superior corrosion resistance and minimal head loss, all while sustaining the strongest possible water pressure after the Deringer is engaged.

The check valve inside the Deringer has been redesigned as well. When discussing the new dual check valve, Scott explained: “[W]hen water initially enters the Deringer to push the check valve to the open position, the check will actually initially separate like a poppet style check. So there's no hinge point that it's swinging on to open and close. … [I]f you have any debris that's coming down the line, there's no hinge point or anywhere for the debris to get caught on.”

The closure design has also been reconsidered to ensure performance and reliability: with less opportunity for debris to get caught in the valve, and the check seal designed to ensure the entire rubber meets the seat at once, any concerns about fouling or backflow are mitigated.

With the Ames Deringer backflow preventer, not only is installation easy, but performance is virtually worry-free.

Serviceability

Worry-free performance means that the Deringer is built to last. But as with any piece of equipment, maintenance and service can be needed.

The Ames Deringer is designed to not only perform, but to be easily serviced and repaired. Unlike other valves on other backflow preventers, an issue with a butterfly valve does not mean the entire valve needs to be replaced. “It's a one-unit body …so if there is an issue with one of the butterfly valves, you don't have to throw the whole valve away. You can easily take it apart and put it back together. There are no special tools required,” Scott said about the Deringer’s serviceability. “We sell repair kits, and they give you all the parts and pieces that you need to repair, if it ever comes down to that.”

Additionally, Watts and Ames have teamed up to also provide easy-to-follow instructional and informational videos on servicing the Deringer, which are available both on YouTube and on the Watts website.

A bonus feature: less freight, less cost

Because the Ames Deringer is shorter and lighter than other backflow preventers on the market, getting the product to your door doesn’t require freight delivery and significant freight costs. If an Ames Deringer distributor isn’t near you, most Deringer models can be shipped via standard ground delivery.

Thoughtful design. Lightweight, reliable performance. Easy repairs if you have to service. A strong network of distributors and standard shipping options. In every way, the Ames Deringer backflow preventer is a game changer.