There are many occasions when it is necessary to install equipment and accessories on the interior walls of an enclosure. Items include heaters, control panels, lights and electrical receptacles, to name a few. The reason for this is twofold.

There are many occasions when it is necessary to install equipment and accessories on the interior walls of an enclosure. Items include heaters, control panels, lights and electrical receptacles, to name a few. The reason for this is twofold.

First, floor space in enclosures is at a premium, so mounting equipment on the walls allows for large equipment like pumps and valves to be placed on the floor. Second, mounting accessories, especially those that are electrical, upon the walls and ceilings reduce the risk of having them come in contact with water or other liquids in the case of a leaking valve or pump. Here are a couple of tips to mounting equipment to the walls.

Tip 1: Consider the Location of the Mounted Equipment

The first tip is to consider the location of where the equipment will be mounted. For example, let’s say you are covering a booster pump that will utilize a control panel to operate it. A good idea is to make sure the control panel is mounted in a location where it is easy to gain access to. The last thing an operator will want to do is climb over equipment to turn the pump on/off on a daily basis. It will also make replacing the control panel that much easier if there is ever a need. This also applies to light fixtures. Make sure to mount them in an area of the ceiling where they provide the needed light but are easy to access to replace bulbs, etc.

Tip 2: Consider the Weight of the Equipment and Accessories

The next tip is to consider the weight of the equipment and accessories that are to be mounted on the walls. Most accessories are fairly light and should not be a problem when mounting them. However, there are times when heavy, bulkier items need to be hung. In this case, you will want to consider what the enclosure walls are made from and use the proper mounting method recommended by the manufacturer of the enclosure.

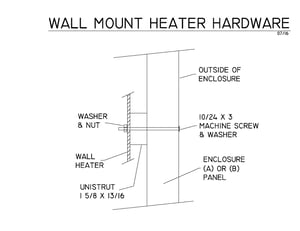

Tip 3: How to Successfully Hang the Equipment

The third and final tip is regarding how to actually hang the equipment on the enclosure wall. Safe-T-Cover enclosures are manufactured using wooden studs in the walls. A stud’s main purpose is to provide strength and stability; however, they also provide a convenient place to hang equipment. Similar to how you would hang something on your walls at home, you can hang equipment on the enclosure walls. If a wooden stud isn’t available, securing a piece of Unistrut on the wall to hang equipment from is another great option. Simply attach the length of Unistrut to the enclosure wall using a couple of machine screws, washers and bolts, and then hang the accessory or equipment from the piece of Unistrut (see attached drawing).

The third and final tip is regarding how to actually hang the equipment on the enclosure wall. Safe-T-Cover enclosures are manufactured using wooden studs in the walls. A stud’s main purpose is to provide strength and stability; however, they also provide a convenient place to hang equipment. Similar to how you would hang something on your walls at home, you can hang equipment on the enclosure walls. If a wooden stud isn’t available, securing a piece of Unistrut on the wall to hang equipment from is another great option. Simply attach the length of Unistrut to the enclosure wall using a couple of machine screws, washers and bolts, and then hang the accessory or equipment from the piece of Unistrut (see attached drawing).

Utilizing the interior walls of an enclosure to hang equipment and accessories can help save valuable floor space and keep equipment dry and out of the way of other equipment. It can also provide potential cost savings by not having to purchase a larger enclosure.