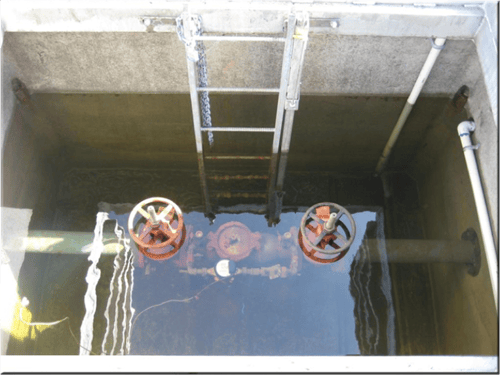

Installing backflow preventers and meters in a utility vault is an unnecessary liability for water jurisdictions and civil engineers, so we’re encouraging a bigger push to install them above ground in a backflow enclosure.

It’s much safer and more cost-effective.

-

1Contact Information

-

2Additional Details

Backflow preventers are critical to protecting our water supply. They keep contaminated water from interacting with drinking water, preventing cross-connection.

Backflow preventers are critical to protecting our water supply. They keep contaminated water from interacting with drinking water, preventing cross-connection. OSHA data indicates that the number of deaths in confined spaces have been steadily increasing over the last 15 years.

OSHA data indicates that the number of deaths in confined spaces have been steadily increasing over the last 15 years. Another major concern is that many

Another major concern is that many