For several years now, water jurisdictions across the country have mandated reduced pressure zone valves, replacing the previously conventional double check assembly. RPZs today are the go-to solution in backflow preventers.

As a result, this paradigm shift has led many to look for insulated backflow covers and enclosures. Design engineers and water authorities alike are seeking the best answer to the question: What prevents a RPZ backflow preventer from freezing?

Let’s look at the two features any insulated backflow cover should have, the proper type and amount of insulation and appropriate ways to keep equipment within a cover heated during the winter.

Insulation: Modular Design Is the Way to Go

A quality backflow enclosure will have polyisocyanurate insulation, cut to the exact dimensions of each wall and roof panel. The wall panels should have R9 insulation, while the roof should have R18. Much like our homes need to have R30 in the ceiling, R18 in an enclosure reduces heat loss and lowers overall energy consumption.

Insulation should at least be mechanically fastened within each panel with retainers, which means it will stay intact and in place during shipment, installation and over the enclosure’s useful life. Take a look at this short video to see how our insulation is installed within a Safe-T-Cover panel.

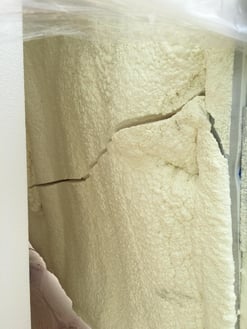

Some backflow enclosure makers insulate their enclosures with spray foam, which can crack, break, deteriorate or detach from the enclosure’s walls. These manufacturers also tend to have a difficult time evenly distributing the foam application. On the other hand, with insulated panels, you have maximum, around-the-clock freeze protection. See the difference for yourself.

The R-value for polyisocyanurate insulation is the highest for rigid-board insulation, averaging 6.5 per inch. Plus, you’re eliminating the risk of air leaks or inconsistent or under-insulated areas.

When you are evaluating a backflow enclosure, make sure it has R18 in the roof and uses rigid insulation panels and not sprayed-on insulation.

How About the Heat?

What good is insulation if you don’t have heat? A heater should be specified if temperatures in your region ever fall below 32 degrees for more than two days.

The decision to install heat is often a pay-me-now-or-pay-me-later proposition. Weather patterns have been crazier than ever in recent years. If a cold snap occurs and the backflow preventer enclosure does not have heat, the RPZ will freeze and you’ll be left with a costly repair bill. We’re letting alone the fact that the water must be shut off while any repairs are made. Any building occupants in this situation will not be happy, or production may be shut down, leading to lost revenue and production. We've seen this happen time and again.

Two types of heaters are available: slab-mounted and wall-mounted heaters. When it comes to backflow preventer assemblies, a slab-mounted heater is your best option—especially if the enclosure roof is insulated.

A slab-mounted heater, as the name suggests, is installed on the floor of the backflow enclosure. It not only provides heat to the RPZ, but it warms riser pipes up to 16 inches beneath the slab as well. Safe-T-Cover’s patented slab-mounted heaters meet all ASSE 1060 requirements. They’ll maintain an interior temperature of 40℉— even with an outside temperature as low as -30℉.

Here’s an image of a slab-mounted heater installation. You can see it’s anchored into the concrete, so it will never move out of place. These heaters can produce as much as 2000 watts and are available in 120V or 240V. You can even outfit the enclosure with power and temperature failure alarms as a precaution.

Here’s an image of a slab-mounted heater installation. You can see it’s anchored into the concrete, so it will never move out of place. These heaters can produce as much as 2000 watts and are available in 120V or 240V. You can even outfit the enclosure with power and temperature failure alarms as a precaution.

The heater offered by most backflow enclosure manufacturers is wall-mounted. If your wall heater is not UL 2021 rated, it must be installed high enough – a minimum of 12 inches – on the wall to avoid contact with water coming from the RPZ. slab-mounted heaters, on the other hand, are UL 2021 certified for wet/damp conditions. This is necessary for any non-watertight enclosure.

A wall-mounted heater guarantees the top of your enclosure will stay warm, but that's not as important as keeping the RPZ itself thawed. Think about it: as a basic scientific principle, heat rises. Since a wall-mounted heater is above the slab, the lower half of the enclosure will not experience maximum freeze protection. A wall-mounted heater will struggle to maintain correct temperature for riser pipes and the backflow preventer itself. Watch this short video and see the difference for yourself.

Much goes into keeping an RPZ safely operational and warm all winter long. An insulated backflow enclosure provides the peace of mind of knowing you have the freeze protection you need (plus a secure locking mechanism for vandal protection). You’ll also eliminate the risk of flooding in your building and the danger of potential cross-connection. Quality insulation is a critical component to ensuring your heat is being contained and evenly distributed throughout your enclosure.

If you’re installing a backflow preventer above ground and outdoors, make sure it’s surrounded by the best enclosure with the best insulation money can buy. Contact us today if you’d like to discuss our approach to insulation or enclosure design.