Pump covers are used to protect pump equipment from theft, vandalism, accidents and to provide a climate-controlled operating environment. When it comes to climate control, enclosures have been traditionally seen as a winterization tool — that's part of the reason they're generically called "insulated aluminum pump covers." They work well for that — keeping equipment safe without requiring wrapping in blankets or attaching insulated bags to the pipes.

Proper winterization considers various factors including outside temperature extremes, protection from the elements, and minimum internal requirements. Insulation can be adapted for particularly demanding environments, like in St. John's Newfoundland where mother nature brings winters that are harsh and windy. However, winterization should only be part of your climate control protection plan. Often, heat is just as serious of an environmental threat to critical pump equipment, even in temperate climates.

Examples of climate control enclosure requirements

Every time the phone rings and one of our engineers answers, there is a good chance we'll encounter a customer with some new needs. Some recent requests include installing a window in a pump cover and designing an industrial enclosure to be installed on top of a building for sound abatement. You may recognize the need in your own applications, or perhaps it will trigger an idea that's related. Here are some different situations in which simple insulation and winterization of your industrial equipment and pump covers would not be enough — going well beyond the stock cover!

- Your automatic glycol make-up pump system only operates in temperatures up to 105 degrees.

- You need remote high- and low-temperature alerts to stay on top of your control valve system.

- Your Grundfos fire pump runs best at 60 degrees Fahrenheit and loses 1% horsepower for every 10 degrees rise in temperature.

- You have to increase the motor size for your booster pump system if the temperature inside the pump cover gets above 104 degrees.

- You have to keep the slab warm in addition to the backflow preventer above it so that the pipes do not freeze and burst.

- The fixed temperature of release for your deluge pump system is 110 degrees Fahrenheit

- Your generator creates enough heat itself to jeopardize long-term operation without some form of air conditioning.

Heating the Equipment & Slab

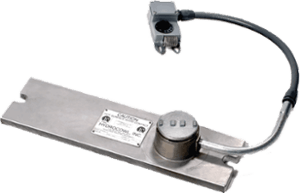

For freeze protections, heaters are widely available for water applications. An ASSE 1060 Class 1 heater will keep the equipment at 40 degrees Fahrenheit even when it is negative 30 degrees outside. Most heaters in the industry are wall-mounted at a minimum of 12 inches off the slab. Remember that heated air rises, so the most efficient heating occurs when the heater is placed as low as possible. For maximum heat retention, look for a heater that bolts directly to the concrete slab and produces both convective heat to the air and conductive heat to the slab. Some heaters installed in this way can provide heat that penetrates as much as 16 inches down into the vertical riser pipes. There is also a need to plan for heating solutions that are designed for wet/damp environments. This is especially important in waterworks applications but should also be a consideration for any industrial or pump covers that are installed outside.

No More Overheating

It is important to remember, however, that maintaining a minimum temperature to prevent pipes from freezing isn’t the only requirement. Other processes are substantially impacted by variations in the viscosity of other fluids (oil for instance) and as noted in some of the examples above, maximum temperature can quickly become a disaster even in temperate zones. Designs should incorporate louvers and exhaust fans for venting when that is adequate. Some pump cover manufacturers can even provide air conditioning. This is vital when the climate is particularly hot or the equipment requires maximum ambient operating temperatures that are lower than venting can provide. Incorporated electronics and controls are increasingly common in industrial equipment installations and they are prone to failure when overheated.

Don't Ignore Climate Control Needs

Climate control should be on your mind when choosing and installing pump covers and other enclosures. If the installation is outdoors, there is a high probability it will need a heater or some sort of vent system. Keep both the environment and the equipment in mind when it comes time to choose climate control. Some devices are likely to freeze and others may overheat. Either way, that will stop production and require maintenance to fix it. Staying proactive with climate control will keep your equipment running smoothly no matter the weather.